Powder coating has rapidly become the preferred choice for many industries and homeowners alike. This advanced process not only offers an aesthetically pleasing finish but also provides superior protection against the elements. In Birmingham, the demand for powder coating Birmingham services is on the rise thanks to its versatility and effectiveness. Throughout this article, we will delve into various aspects of powder coating, including its techniques, benefits, applications, and how to ensure you work with the right service provider.

Understanding Powder Coating Techniques

The Basics of Powder Coating

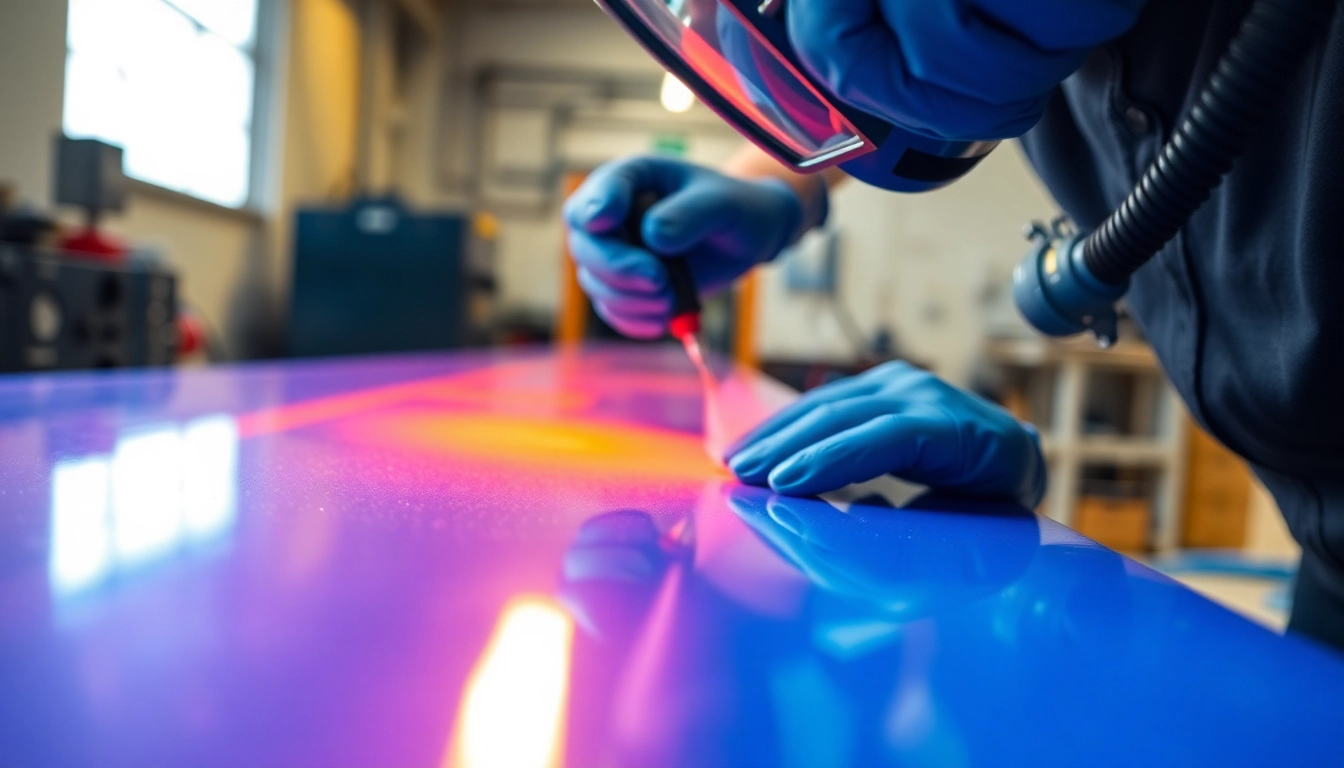

Powder coating is a dry finishing process that employs thermosetting powder. It is applied electrostatically and cured under heat to form a durable skin. The process begins with the preparation of the metal surface; this includes cleaning, sanding, and sometimes treating with a primer. Once prepared, the powder is sprayed onto the surface using a specialized gun, where it adheres due to electrostatic charge. The coated item is then heated in an oven, which causes the powder to melt, flow, and ultimately cure into a hard finish.

Different Types of Powder Coatings

There are several types of powder coatings available, including polyester, epoxy, hybrid, and urethane powders, each suited for various applications:

- Polyester Powder Coatings: Known for their excellent weather resistance, these are commonly used for outdoor applications, including patio furniture and automotive components.

- Epoxy Powder Coatings: These provide a strong, chemical-resistant finish, making them ideal for industrial applications.

- Hybrid Powder Coatings: Combining the best properties of both polyester and epoxy, hybrids offer great flexibility and durability, suited for both interior and exterior surfaces.

- Urethane Powder Coatings: These boast exceptional hardness and abrasion resistance, making them ideal for high-wear applications.

Applications of Powder Coating in Birmingham

Powder coating has found a wide range of applications in Birmingham, catering to both businesses and individual consumers. Key areas of usage include:

- Automotive Industry: A favorite among car enthusiasts for finishing vehicle parts.

- Home Furnishings: Appliances and lawn furniture benefit from the tough, attractive finish that powder coating provides.

- Industrial Equipment: From handrails to outdoor machinery, powder coating helps protect against rust and wear.

- Custom Projects: Individuals often use powder coating for bespoke items, ensuring a unique finish on custom metalwork.

Benefits of Choosing Powder Coating

Durability Compared to Standard Paint

One of the foremost advantages of powder coating is its durability. It is more resilient to chipping, scratching, and wear than traditional paint. The thick finish that powder coating creates can withstand extreme temperatures, making it suitable for items exposed to the elements. Furthermore, it provides superior protection against chemicals, moisture, and UV radiation, ensuring that your investment lasts longer.

Eco-friendly Aspects of Powder Coating

In an age where sustainability is crucial, powder coating stands out as an eco-friendly choice. Unlike traditional liquid paints, powder coatings contain no solvents and release minimal volatile organic compounds (VOCs) into the atmosphere, making it a healthier option for both the environment and for workers engaging in the coating process. Additionally, overspray from powder coating can be collected and reused in the process, minimizing waste.

Cost-effectiveness in the Long Run

While the initial costs for powder coating may be higher than painting, its longevity offers significant savings over time. The durability of powder-coated surfaces means they require less frequent maintenance and replacement, which leads to lower costs over the lifespan of the product. Furthermore, the speed of the powder coating process allows for quicker turnaround times than traditional paints.

Choosing the Right Powder Coating Provider in Birmingham

Evaluating Service Providers

Finding the right powder coating service in Birmingham requires diligent research. Start by looking for providers with a solid reputation in the industry. Check online reviews, testimonials, and case studies to assess the quality of their work. Local directories and platforms such as Yelp can also provide insights into customer satisfaction and service quality.

What to Look for in a Powder Coating Company

When evaluating potential powder coating companies, consider the following factors:

- Experience: Look for firms with a proven track record in powder coating, particularly those with experience in your specific industry.

- Facility Equipment: Ensure that the company has modern, well-maintained equipment for high-quality finishes.

- Customization Options: A good company will offer a variety of colors and finishes, as well as the ability to handle custom projects.

- Compliance and Certifications: Verify that the company follows industry standards and regulations to ensure safety and quality.

Questions to Ask Before Hiring

Before deciding on a powder coating provider, it’s essential to ask the right questions. Consider inquiring about:

- What specific processes do you use for surface preparation?

- What types of powders do you offer, and which would you recommend for my project?

- Can you provide references or examples of similar projects you’ve completed?

- What is the expected turnaround time for my project?

- Do you offer warranties or guarantees on your work?

Common Uses of Powder Coating

Automotive Powder Coating Applications

In the automotive industry, powder coating is increasingly popular for both exterior and interior components. Its ability to provide a durable, high-quality finish makes it ideal for wheels, bumpers, and parts susceptible to everyday wear and tear. Moreover, it offers manufacturers the flexibility to meet diverse design and color requirements while ensuring a consistent finish across multiple items.

Powder Coating for Home and Garden Projects

For homeowners, powder coating can significantly enhance the aesthetics and durability of outdoor furniture, fencing, and decorative art pieces. Items like patio tables, chairs, and grilles benefit from powder coating by resisting rust and corrosion while providing a striking appearance. Furthermore, many homeowners appreciate the ability to choose custom colors that complement their outdoor decor.

Industrial Applications of Powder Coating

Industrially, powder coating is used extensively on machinery, tools, and components. Its resistance to harsh chemicals makes it a go-to option for parts that will be exposed to corrosive environments. Further, items such as conveyor belts and racks that undergo constant physical wear also benefit from the protective qualities of powder coating, which prolongs their functional lifespan.

Maintenance and Care of Powder Coated Surfaces

Cleaning and Maintenance Guidelines

Maintaining powder-coated surfaces is relatively straightforward. Regular cleaning with soap and water is typically sufficient to remove dirt and grime. For tougher stains, a mild abrasive may be applied, but it’s essential to avoid harsh chemicals that could damage the finish. Moreover, regularly inspecting the coated surface can help identify any early signs of wear or damage.

Repairing Minor Damage to Powder Coatings

While powder coatings are durable, they are not indestructible. Minor chips or scratches can be repaired using touch-up spray paints specifically designed for powder-coated surfaces. It’s advisable to handle repairs promptly to prevent moisture from penetrating and causing further material degradation.

Longevity and Lifespan of Powder Coatings

The lifespan of a powder-coated finish can vary based on environmental factors and the quality of the application. Under optimal conditions, a well-applied powder coat can last anywhere from 10 to 25 years. However, factors such as prolonged exposure to harsh UV light or extreme weather conditions can affect longevity. To maximize the lifespan, proper maintenance and care are crucial.