Understanding Thermal Management Materials

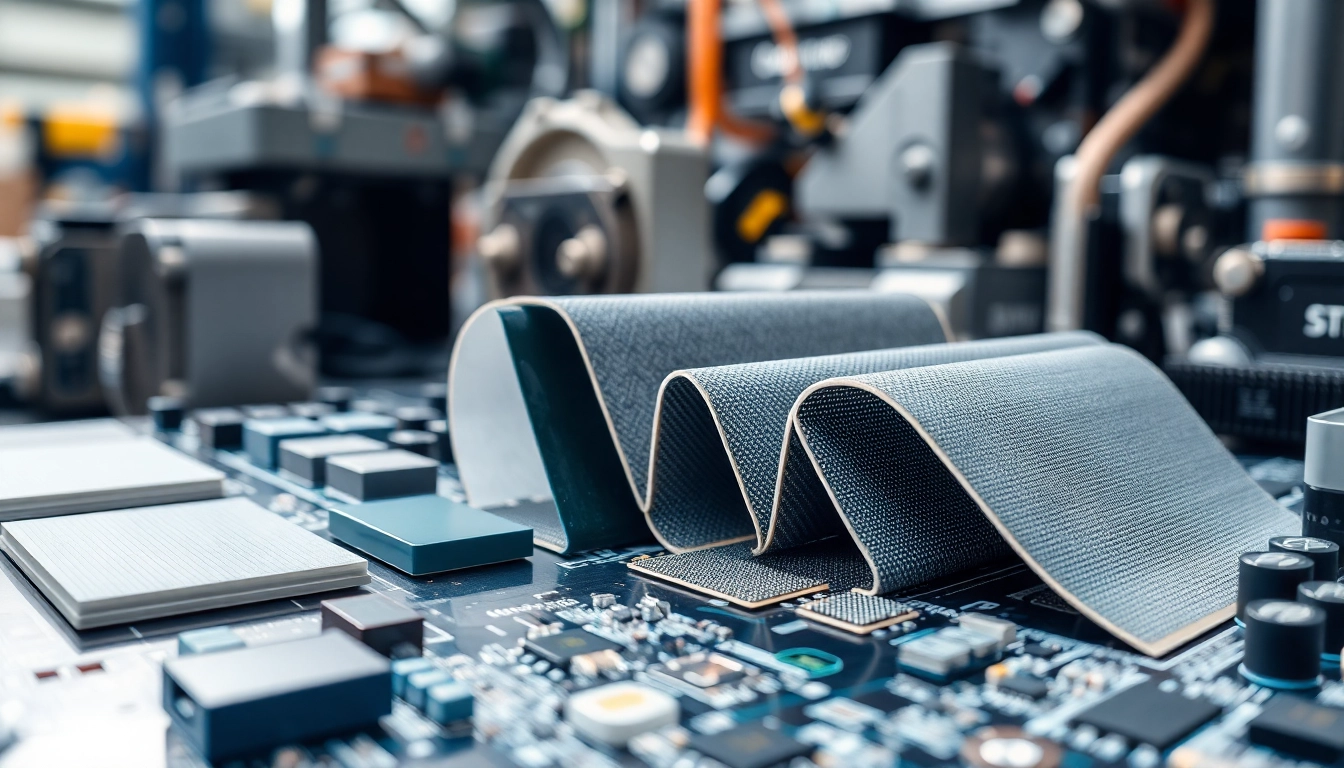

What are Thermal Management Materials?

Thermal management materials refer to a diverse array of substances that facilitate effective heat dissipation, ensuring optimal performance in various electronic devices and components. These materials are engineered to have superior thermal conductivity properties, allowing the transfer of heat away from heat-generating components efficiently. They act as insulators or conductors, depending on their application, ensuring that electronic devices operate within safe temperature limits. In essence, thermal management materials are crucial for maintaining functionality and reliability in everything from smartphones to electric vehicles. To explore more about these innovative materials, you can visit thermal management materials.

Importance of Thermal Management in Electronics

The importance of thermal management in electronics cannot be overstated. As electronic devices become more compact and powerful, the heat generated by their circuitry continues to rise dramatically. Efficient thermal management is vital to prevent overheating, which could lead to reduced performance, circuit failure, or complete device breakdown. For instance, high-performance processors generate substantial heat, and without effective thermal solutions, their longevity and reliability could be compromised.

Moreover, effective thermal management directly correlates with energy efficiency. Devices that manage heat effectively consume less power, leading to lower operational costs and reduced environmental impact. In summary, thermal management is an essential component of modern electronics, influencing product design, performance, and sustainability.

Types of Thermal Management Materials

Thermal management materials can be categorized into several types, each designed for specific applications and requirements:

- Thermal Interface Materials (TIMs): These materials create an effective thermal conduction path between heat-generating components and heat sinks or other dissipation elements. They can include thermal greases, adhesives, and gels.

- Thermal Pads: Composed of soft, conformable materials, thermal pads fill gaps between surfaces to enhance heat transfer. They are particularly useful in scenarios where uneven surfaces are present.

- Phase Change Materials (PCMs): These materials absorb and release substantial amounts of heat as they transition between solid and liquid states. They are particularly useful in applications where temperature control is crucial.

- Heat Spreaders: Made of metals or composites, heat spreaders distribute heat over a larger area to minimize localized hot spots.

- Thermal Insulation Materials: Designed to prevent heat flow, these materials protect sensitive components from excessive heat.

Key Applications of Thermal Management Materials

Thermal Interface Materials in Electronics

In electronic systems, thermal interface materials play a critical role in ensuring efficient heat transfer between components. They can enhance reliability and performance by ensuring proper thermal contact, thereby preventing thermal build-up. An example includes the application of thermal greases in CPU heat sinks, which fill microscopic gaps that would otherwise limit heat conduction.

Heat Dissipation Applications in Consumer Electronics

Consumer electronics, including smartphones, laptops, and gaming consoles, rely heavily on thermal management materials. These devices integrate powerful processors that generate significant heat. Utilizing materials such as thermal pads and TIMs can prevent overheating while maintaining device performance. The introduction of advanced thermal management materials has also enabled manufacturers to create thinner and lighter devices without compromising functionality.

Thermal Management in Electric Vehicles

The electric vehicle (EV) sector is an area where effective thermal management is crucial for safety and performance. Lithium-ion batteries, which are the backbone of EV technology, generate heat during operation and charging. Thermal management materials help in regulating battery temperatures, which is vital for maximizing efficiency and extending battery life. Additionally, thermal solutions are instrumental in managing the temperatures of electric motors and electronic control units (ECUs).

Choosing the Right Thermal Management Materials

Evaluating Material Conductivity and Thermal Resistance

When selecting thermal management materials, it is imperative to evaluate their thermal conductivity and thermal resistance. Materials with high thermal conductivity facilitate efficient heat dissipation, while those with high thermal resistance can hinder heat transfer and must be used judiciously. The required performance characteristics vary depending on the application, so understanding the specific thermal requirements is essential.

Factors Influencing Material Selection

Several factors influence the selection of thermal management materials, including:

- Operating Temperature: Understand the temperature range that your application requires to ensure that the chosen material can perform effectively without degradation.

- Mechanical Properties: Evaluate the mechanical strength and flexibility of the material, especially for dynamic applications.

- Cost-Effectiveness: Budget constraints can dictate material options; thus, a balance between quality and cost must be achieved.

- Environmental Considerations: Some materials may not perform well under certain environmental conditions, which should be considered based on the application’s setting.

How to Test Thermal Management Materials

Testing thermal management materials is a vital step in ensuring they meet application requirements. Typical testing methods include:

- Thermal Conductivity Tests: Measure the material’s ability to conduct heat, typically using standardized tests like the guarded hot plate method.

- Thermal Resistance Tests: Assess the resistance to heat flow under specified conditions, which can help identify suitable materials for critical applications.

- Durability Tests: Subject materials to mechanical and thermal cycling to evaluate long-term performance.

Best Practices for Implementing Thermal Management Solutions

Comparative Analysis of Leading Materials

To effectively implement thermal management solutions, it is advisable to perform a comparative analysis of the leading materials on the market. Factors for comparison should include thermal performance, ease of application, cost, and long-term reliability. Such an analysis allows manufacturers to select the most appropriate material for their specific needs while potentially uncovering innovative solutions that may have been overlooked.

Application Methods for Effective Thermal Management

Proper application techniques are critical in ensuring effective thermal management. For thermal interface materials, the application process may include:

- Surface Preparation: Surfaces should be cleaned and free from contaminants to ensure maximum surface contact.

- Consistent Application Thickness: Materials should be applied uniformly to avoid creating air pockets that can reduce thermal conductivity.

- Proper Curing or Setting: Allowing materials to cure or set properly is vital for achieving optimal performance.

Common Challenges and Solutions in Material Usage

Challenges may arise following the application of thermal management materials. Common issues include:

- Inconsistent Performance: Variability in material properties can lead to unexpected thermal performance issues, which can be mitigated by thorough quality control and standardized testing.

- Material Degradation: Materials may degrade over time due to exposure to heat or environmental factors. Selection of high-quality, durable materials can alleviate this risk.

- Application Errors: Improper applications can result in inadequate heat transfer. Adhering to manufacturer guidelines during application can optimize performance.

Future Trends in Thermal Management Materials

Innovations in Material Technology

The landscape of thermal management is continuously evolving with innovations leading to the development of advanced materials. These include nano-enhanced materials that take advantage of nanotechnology to improve thermal conductivity and reduce weight. Emerging biodegradable thermal management materials may also make waves in industries focused on sustainability.

Market Trends and Forecasts for Thermal Materials

The market for thermal management materials is projected to grow exponentially as the demand for high-performance electronics increases. This growth is particularly robust in sectors like automotive, consumer electronics, and renewable energy, where maximizing efficiency is crucial. Industry reports suggest that advancements in thermal management are set to drive innovation, leading to a wider adoption of efficient materials.

Environmental Considerations and Sustainability

As the focus on sustainability intensifies globally, the thermal management materials industry is shifting toward eco-friendly options. Manufacturers are increasingly exploring materials that are recyclable or less harmful to the environment. This movement not only helps reduce waste but also aligns with the broader trend towards environmentally responsible manufacturing practices.