Understanding Custom Steel Fabrication

In an era of rapid technological advancement and innovative designs, the significance of custom steel fabrication cannot be overstated. This process, which involves the creation of specific steel structures tailored to the requirements of various industries, showcases the versatility and strength of steel as a building material. From construction to aerospace, custom steel fabrication plays a crucial role across multiple sectors, allowing for the development of unique solutions that meet the needs of modern society.

What is Custom Steel Fabrication?

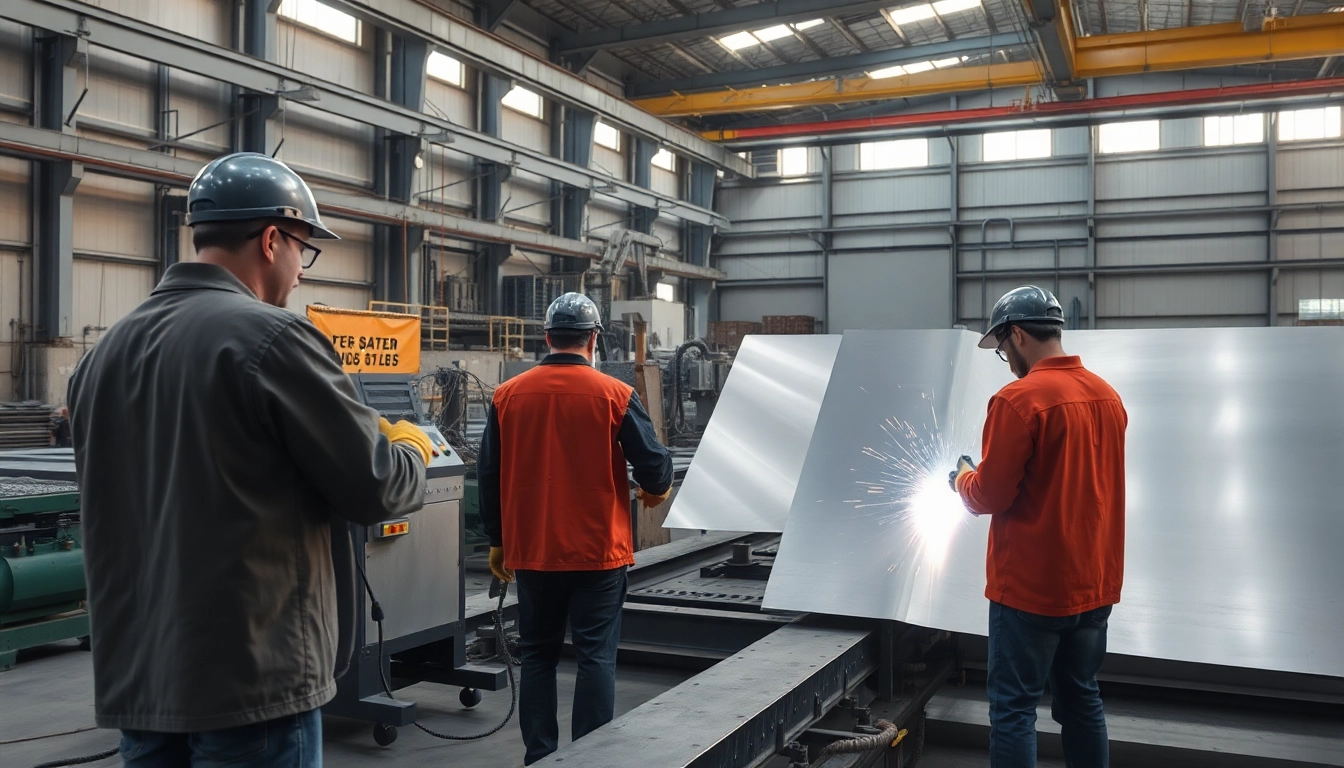

Custom steel fabrication refers to the process of shaping steel into various forms and structures as per specific designs and requirements. This can involve cutting, bending, welding, and assembling steel components to create finished products. Unlike mass production techniques, which yield identical products, custom fabrication emphasizes flexibility and design intricacy, allowing clients to obtain tailored solutions that fit precise specifications. Fabricators often employ advanced machinery and techniques, including CNC (Computer Numerical Control) machining, to achieve high levels of accuracy and repeatability.

The Importance of Custom Steel Fabrication in Modern Industry

The importance of custom steel fabrication extends beyond mere construction; it enables businesses to innovate and adapt to changing market demands. Custom fabrication serves as a vital backbone of numerous industries, from manufacturing to energy, providing the necessary components for infrastructure development and product manufacturing. Whether it’s creating unique architectural designs or fulfilling precise engineering requirements, custom steel fabrication offers unparalleled durability and robustness, ensuring safety and longevity in the products developed.

Key Techniques in Custom Steel Fabrication

Several key techniques are employed in custom steel fabrication, enhancing the flexibility and capability of fabricators:

- Cutting: This can involve methods like laser cutting, plasma cutting, and waterjet cutting, all of which help achieve precise dimensions and intricate designs.

- Bending: Techniques such as press braking allow steel sheets to be bent into specified angles and shapes, essential for creating components like brackets and frames.

- Welding: Various welding techniques, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), are used to join steel pieces together, ensuring structural integrity.

- Finishing: Processes like sandblasting, painting, or galvanizing enhance the aesthetic appeal and protect the steel from corrosion.

Popular Applications of Custom Steel Fabrication

Construction Projects Utilizing Custom Steel Fabrication

The construction industry widely utilizes custom steel fabrication to create structural elements such as beams, columns, and frames. These components are essential for constructing buildings, bridges, and other infrastructures, offering strength and stability. Custom steel fabrication enables architects and engineers to create innovative designs, such as cantilevers and curved structures, which would be difficult or impossible to achieve with standard components.

Custom Steel Fabrication in Automotive Manufacturing

Automotive manufacturing relies heavily on custom steel fabrication for producing various parts, including chassis, frames, and body panels. The ability to fabricate components that meet stringent safety and performance standards is vital in the automotive sector. With the push toward lightweight vehicles, custom fabrication enables the use of advanced steel grades that offer superior strength while reducing weight.

How Custom Steel Fabrication Benefits the Aerospace Sector

In the aerospace industry, the requirements for precision, durability, and weight considerations make custom steel fabrication indispensable. Fabricators work closely with aerospace engineers to produce components that can withstand extreme conditions, including high temperatures and varying pressure levels. The customization capabilities allow for the development of lightweight yet robust structures, enhancing the overall performance of aircraft.

Choosing the Right Custom Steel Fabrication Partner

Evaluating Experience and Expertise in Custom Steel Fabrication

When selecting a fabrication partner, experience and expertise are critical factors. A seasoned provider brings knowledge of industry standards, material properties, and fabrication techniques, which can significantly impact project outcomes. Reviewing past projects and client testimonials can provide insight into the company’s ability to handle specific requirements effectively.

Understanding Customization Options and Capabilities

It is essential to assess the customization options a fabrication shop offers. This includes the range of materials available, the types of fabrication techniques employed, and the extent to which they can engage in product design. A good fabrication partner will provide options for various grades of steel, allow for alterations in design throughout the process, and possess the capability to scale production according to project demands.

Assessing Quality Control in Custom Steel Fabrication

Quality control is a fundamental aspect of custom steel fabrication. It plays a vital role in ensuring that the final product meets specification and performance requirements. Inquire about the quality assurance processes in place, such as inspections, certifications, and adherence to industry standards. Effective quality control measures can prevent costly mistakes and delays in production.

Cost Considerations in Custom Steel Fabrication

Factors Influencing the Cost of Custom Steel Fabrication

Several factors influence the cost associated with custom steel fabrication, including:

- Material Costs: The type and grade of steel used significantly affect overall pricing.

- Complexity of Design: More intricate designs require advanced techniques and more labor, increasing costs.

- Volume of Production: Custom fabricators often provide better pricing for larger runs due to economies of scale.

- Lead Time: Tight deadlines can incur rush fees, so planning is essential to manage costs.

Budgeting for Custom Steel Fabrication Projects

Budgeting for a custom steel fabrication project requires careful consideration of all potential expenses. Create a detailed quote that outlines material, labor, and overhead costs. It’s also wise to establish a contingency budget to account for unforeseen expenses that may arise during the fabrication process, which can include design adjustments or material shortages.

Ways to Optimize Costs Without Sacrificing Quality

To optimize costs in custom steel fabrication without compromising quality, consider the following strategies:

- Material Selection: Choose materials that meet performance criteria without excess expenditure.

- Design Simplification: Streamline designs to reduce complexity, which can lower labor costs.

- Continuous Communication: Maintain open lines of communication with your fabrication partner to address any issues early and prevent costly delays.

Future Trends in Custom Steel Fabrication

Innovations Shaping the Future of Custom Steel Fabrication

As technology continues to evolve, so too does the field of custom steel fabrication. Innovations such as 3D printing of metal components and advancements in materials science are shaping the future of the industry. These technologies not only allow for more detailed and complex designs but also enhance sustainability by reducing waste and improving efficiency across the fabrication process.

The Role of Automation in Custom Steel Fabrication

Automation is revolutionizing custom steel fabrication, allowing for higher production speeds and improved precision. Automated machines can perform repetitive tasks more effectively than manual labor, reducing human error while increasing throughput. As automation technology becomes more accessible, it enables fabrication shops to remain competitive in a fast-paced industry.

Sustainability Practices in Custom Steel Fabrication

Sustainability is becoming increasingly important in the manufacturing sector, including custom steel fabrication. Practices such as recycling scrap metal, reducing energy consumption during fabrication, and selecting environmentally-friendly materials are gaining traction. Companies that embrace sustainable methods not only contribute positively to the environment but also appeal to a growing base of eco-conscious consumers.