Understanding Speedglas Welding Helmets

Welding is an essential activity within various industries, from manufacturing to construction, requiring proper equipment to ensure safety and efficiency. Among the most important tools for a welder is their helmet. When discussing welding helmets, the name speedglas stands out as a leading brand. This article will explore the capabilities and features of Speedglas welding helmets, their benefits, popular models, and how to choose and maintain them properly to guarantee safety and performance.

What is Speedglas Technology?

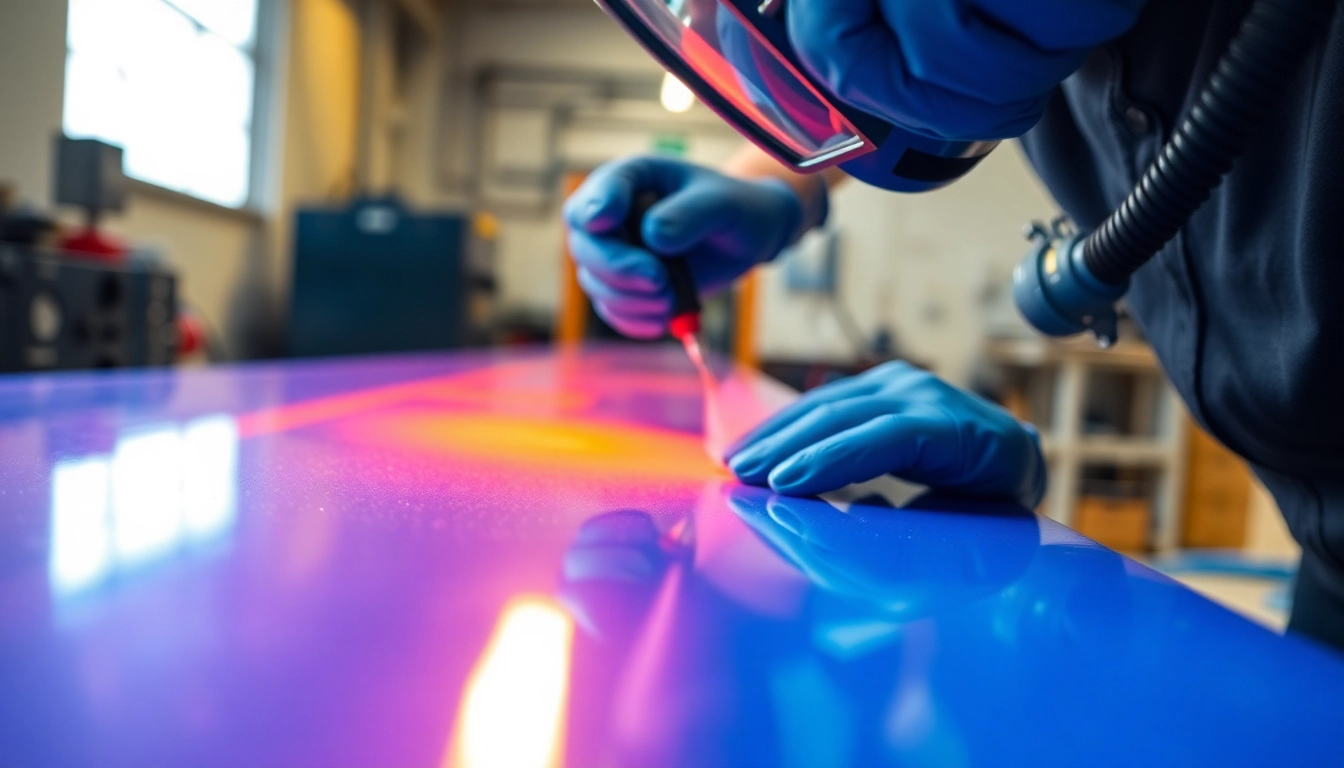

Speedglas technology represents a significant advancement in welding safety, equipped with features designed to protect the welder effectively. The brand has a legacy of innovation, notably introducing auto-darkening filters (ADF) that rapidly adjust the lens tint in response to arc light. This capability allows welders to maintain visibility without frequent manual adjustments.

Speedglas welding helmets also incorporate advanced optics for clearer vision and reduced distortion, making it easier to see weld pools. This precise viewing capability is essential for creating high-quality welds and improving overall workflow. Additionally, many Speedglas models are designed to integrate with respiratory protection systems, ensuring welders are shielded from hazardous fumes and particles.

Key Features of Speedglas Helmets

- Auto-Darkening Filters: These filters automatically adjust to varying light conditions for optimal vision.

- Comfortable Fit: Many Speedglas helmets are designed with ergonomic features, including adjustable headgear and lightweight materials, ensuring comfort during long welds.

- Respiratory Protection Integration: Some helmets are compatible with powered air-purifying respirators (PAPR), providing a complete protection solution.

- Durability: Built to withstand tough environments, Speedglas helmets are rugged and reliable, making them ideal for professional use.

- Versatility: Suitable for various welding applications including MIG, TIG, and stick welding.

Comparing Speedglas with Other Brands

Speedglas is frequently compared with other top helmet manufacturers like Miller, Lincoln Electric, and Optrel. While each brand evaluates its strengths, Speedglas offers distinct advantages that make it a preferred choice among professionals:

- Innovative Technology: Speedglas’s pioneering auto-darkening lens technology places it ahead in user convenience and safety.

- Quality Assurance: Speedglas helmets undergo rigorous testing to meet high safety standards, ensuring they provide reliable performance in critical situations.

- User Feedback: Welders often report higher satisfaction levels with the visibility and comfort of Speedglas helmets compared to competitors.

Benefits of Using Speedglas Helmets

Enhanced Safety and Protection

Safety is paramount in welding, and Speedglas helmets provide comprehensive coverage that meets and exceeds industry standards. The helmets effectively protect against:

- UV and Infrared Radiation: Speedglas helmets block harmful radiation emitted during welding processes, reducing the risk of eye damage.

- Physical Hazards: Their construction protects against impacts and falling debris, crucial for those working in industrial environments.

- Fume and Particulate Protection: Models with integrated PAPR systems safeguard welders from toxic fumes and particles.

Improved Visibility During Welding

The auto-darkening function of Speedglas helmets enhances visibility, allowing welders to see their work clearly before, during, and after the welding process. This feature minimizes the risk of errors, helps improve the quality of welds, and leads to faster project completion times.

Moreover, the enhanced optics used in Speedglas helmets provide a more natural color spectrum and a wider field of view. This dramatically improves a welder’s ability to gauge heat and the material being welded, leading to increased precision.

Comfort and Ergonomic Design

Long welding sessions require a helmet that delivers comfort alongside protection. Speedglas helmets boast an ergonomic design that distributes weight evenly across the head, thus decreasing fatigue. Many models include:

- Adjustable Headgear: This feature allows for individual customization, ensuring a snug yet comfortable fit.

- Lightweight Materials: Utilizing advanced composite materials helps reduce the helmet’s overall weight, enhancing comfort for prolonged use.

- Ventilation: Some helmets offer passive or active ventilation, improving airflow and reducing heat build-up inside the helmet.

Popular Speedglas Helmet Models

The Speedglas 9100XXi Overview

The Speedglas 9100XXi represents one of the premier models in the Speedglas lineup, renowned for its comprehensive features aimed at professional welders. This helmet includes:

- Auto-Darkening Filter: With a sensitivity setting that adjusts to different welding types, enhancing usability.

- Wide Viewing Area: Compared to previous models, it offers a 30% larger lens area.

- Comfortable Headgear: Designed for extended wear, it ensures that professionals can work efficiently without discomfort.

Exploring the Speedglas G5 Series

The Speedglas G5 series showcases modern design alongside advanced technology. Notable features include:

- TAP Technology: This user-friendly feature allows welders to switch modes seamlessly by simply tapping on the helmet’s side.

- Integrated Respiratory Protection: The G5 series can integrate with 3M PAPR systems, allowing for effective comfort and protection against inhalation hazards.

- Lightweight Construction: Designed for ultimate comfort and versatility in various welding applications.

Accessories to Enhance Your Speedglas Experience

To maximize the benefits of Speedglas helmets, various accessories are available:

- Replacement Lenses: Regular replacement of the outer protective lens is crucial for maintaining visibility.

- PAPR Systems: For those needing respiratory protection, integration with 3M’s lightweight, effective PAPR systems is recommended.

- Additional Headgear: Upgrades to headgear systems improve fit and comfort.

How to Choose the Right Speedglas Helmet

Assessing Your Welding Needs

Before selecting a Speedglas helmet, assess your specific welding requirements. Are you primarily a MIG, TIG, or stick welder? Each welding method can necessitate different features in a helmet. Consider factors such as:

- Type of Welding: Identify the predominant type of welding you do and choose a model that enhances visibility and comfort for that specific process.

- Frequency of Use: For daily welders, investing in a higher-end model with advanced features may provide the best long-term value.

- Work Environment: Depending on the setting, you may need additional protections, such as respiratory systems or flame-resistant materials.

Price vs. Performance Analysis

When considering your purchase, analyze the price in relation to the helmet’s features and performance. High-end models, such as the Speedglas 9100XXi, may come with higher costs but offer better visibility, technology, and comfort. Balance your budget against the expected use, and remember that investing in quality may prevent future injuries or product replacements.

Customer Reviews and Recommendations

Examining customer reviews can provide invaluable insights into specific models and their real-world performance criteria. Look for feedback focusing on comfort, ease of use, and the effectiveness of protective features. Popular platforms like Amazon, welding forums, and professional review sites often feature detailed customer experiences that could steer your final decision.

Maintaining Your Speedglas Helmet

Cleaning and Care Best Practices

Proper maintenance maximizes the lifespan and effectiveness of your Speedglas helmet. Follow these care guidelines:

- Regular Cleaning: Clean the helmet exterior and visor using soft cloths and non-abrasive cleaning solutions to avoid scratching.

- Inspect for Damage: Regularly check the helmet for wear and tear, especially the auto-darkening lens and headgear components.

- Storage: Store the helmet in a protective bag or case to minimize exposure to dust and physical damage when not in use.

Extending the Lifespan of Your Helmet

To help ensure your helmet continues to perform optimally over time:

- Avoid Extreme Temperatures: Protect your helmet from high heat or cold conditions that may damage its components.

- Usage Guidelines: Follow the manufacturer’s guidelines on usage and replacement schedules to maximize safety and performance.

- Replace Filters and Lenses: Regularly replace auto-darkening filters and lenses as their performance diminishes over time.

When to Replace Your Speedglas Helmet

Understanding when to replace your helmet is key to maintaining safety standards. Signs that replacement is necessary include:

- Visible Damage: Cracks or significant scratches impede visibility and protective capability.

- Outdated Technology: If your helmet lacks core features like auto-darkening functions, consider upgrading.

- Frequent Use for Years: Replace helmets that have been in active use for three to five years to ensure maximum safety compliance.